I had a LOT of this Galvanized Steel Roof Flashing leftover (like 9 feet since they only sell this stuff in 10 foot lengths) from when I made faux locker tags.

Remember those? They take 1-2 INCHES of flashing. And here I was with this long piece of razor sharp metal hanging around in my garage. I really wanted to use it for something.

Remember those? They take 1-2 INCHES of flashing. And here I was with this long piece of razor sharp metal hanging around in my garage. I really wanted to use it for something.

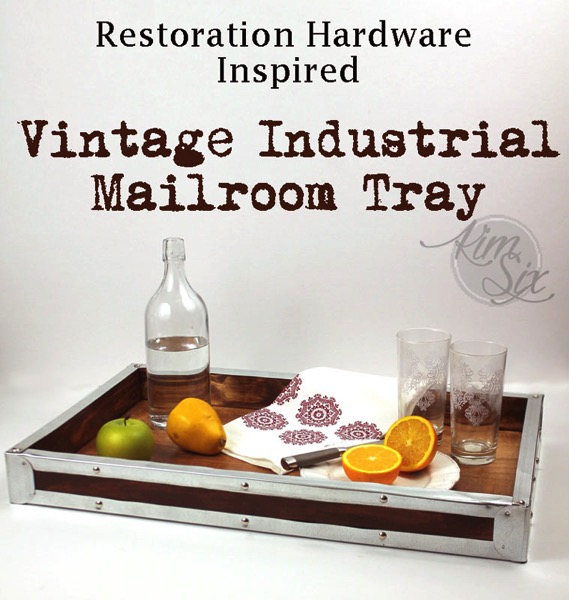

So I was poking around the internet looking for something I could use it on, when I stumbled upon these Mailroom trays from Restoration Hardware. At $200 a pop I thought they were worth trying to knock off. I wouldn’t get that patina on the metal, but more like the shine of vintage aluminum.

And here is the result:

I have to say.. I LOVE IT. (And it seriously is not normally my style.)

I have to say.. I LOVE IT. (And it seriously is not normally my style.)

The rivits and shiny metal remind me of an old metal airplane or something.

Plus.. the best part.. I used ONLY things I already had on hand.

Plus.. the best part.. I used ONLY things I already had on hand.

What did I use?

SUPPLY LIST:

Sanded plywood (I had some leftover from my Pull Out Cabinet Shelves project)(One) 6 ft 1x3”

(One) 10 ft length of Galvanized Steel Roof Flashing (the thinner the better)

3/4” Flat head wiring nails or Furniture Tacks (i had a pack of these I found at the Re-Store and was saving for a rainy day) You want them to have a head so it looks like “rivets”

1-1/4” self-tapping screws

Wood Stain/Polyuratane (I used Polyshades in American Chestnut)

Tool List (check out my favorite tool picks):

Circular Saw or Table Saw (to rip down the plywood)

Miter Saw or Hand Saw (to cut down the 1x3s)

Drill/Driver

Tin Snips

Rubber Mallet

Protective Leather Gloves

Hammer

Bar Clamps

Sandpaper

ASSEMBLY INSTRUCTIONS:

My tray was 22 inches by 13 inches, but you could make it any size.CUT LIST:

Plywood:

22” x 11.5”

1 x 3:

(2) @22”

(2) @ 13”

Flashing:

(2) @ 23” Split down the center (cut at the bend line)

(2) @ 14” Split down the center

(4) @ 3” NOT split down the center

Screw the tray edges onto the

I predrilled the holes along with using self tapping screws, just to prevent splitting.

Now you can stain your tray (or paint it) so that it can dry while you prepare the metal trim.

Now you can stain your tray (or paint it) so that it can dry while you prepare the metal trim.Next you want to take your strips of flashing (remember you have cut them to length and then split them the long ways along the bend in the metal) and create a vice for them. You will need 2 pieces of 1x3 (or any 1-by will do) because you need to make sure the metal covers that top edge of the tray. Clamp the metal upright between the boards (making sure it is pushed all the way to the bottom) and then clamp the boards to the table.

Next, while wearing gloves, push the metal over the edge of the board creating an “L” shape.

Next, while wearing gloves, push the metal over the edge of the board creating an “L” shape.  It will be hard to bend, but once you have it started, you can use a mallet to really level it off. (I even bent it a little past 90 degrees once I took it out of the vice, to make sure I got a really tight fit on the boards.

It will be hard to bend, but once you have it started, you can use a mallet to really level it off. (I even bent it a little past 90 degrees once I took it out of the vice, to make sure I got a really tight fit on the boards.

Before attaching the strips to your tray, MAKE SURE YOU SAND THEM. They are super sharp (especially the edge you cut with the tin snips) so you don’t want to cut yourself on your tray.

Next you want to attach your flashing strips. I liked the rivit look so I used these furniture tacks.

I attached them with two nails on the short size and 3 nails on the long side.

I attached them with two nails on the short size and 3 nails on the long side.  I also used a nail on the top at each corner. Here is what they tray looked like with the strips in place.

I also used a nail on the top at each corner. Here is what they tray looked like with the strips in place.

Finally, you want to cut corner pieces out to cover the seams (and sharp edges). I just made a template out of paper and then used that to trace onto the metal in Sharpie. Once again, make sure you SAND THE EDGES.

I didn’t have enough furniture tacks to attach the corners (and I didn’t want to buy anything extra for this project) so I used wiring nails. I think it looks AWESOME:

The final tray is so industrial and fun. Not like a regular old woodworking project.

And the tacks totally look like rivets.

And the tacks totally look like rivets.

It even goes okay with my boring transitional living room.

I may just be a convert yet!

I may just be a convert yet!

If you liked this project, you may want to check out these fun builds: