It is that time again.. The Build It Blog Hop Challenge, and this month's theme was: REPURPOSE IT!

You have no idea how long I hemmed and hawed and walked around the thrift store trying to think of a project idea that wasn't lame.

You have no idea how long I hemmed and hawed and walked around the thrift store trying to think of a project idea that wasn't lame. It is HARD. Some days I think "everything cool has already been done." But all my fellow bloggers came up with some fantastic projects so NO EXCUSES!

I originally built my cabinet door cornhole boards as my submission to this challenge, but then one afternoon, inspiration struck me.. AT THE DOLLAR STORE. A huge pile of wooden handled hammers...

What can you do with a bunch of claw hammers?

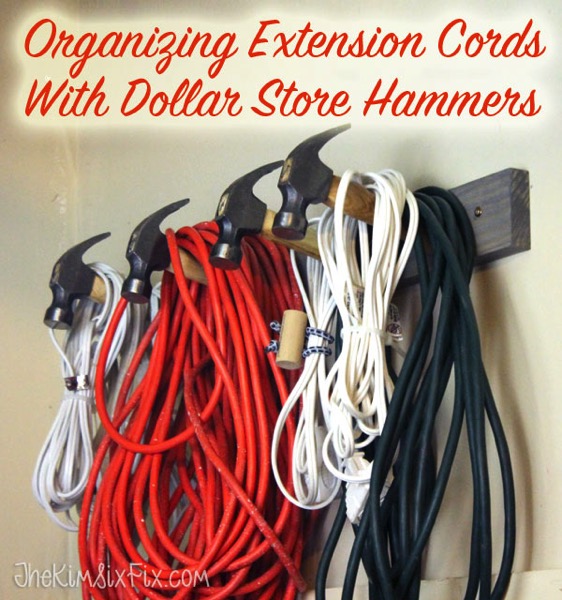

I am calling my project a ‘coat rack’ because that is was the easiest way to label it, but really, as a California girl I don’t need a lot of coat storage. What I DO need to organize are my extension cords in my workshop.. So that is actually what I’m using it for:

And the best part of this project? It only cost me FOUR BUCKS!! (I couldn’t even buy a set of large hooks for $4!)

The supplies I used were.. four hammers. From the dollar store ($4) and a piece of scrap 1x2. (free)

Now, these aren’t really great hammers, but who cares? I’m not using them for nailing! (If you can't find them at the dollar store, the next cheapest I've seen them for is $4 at Harbor Freight.

There is really only one tricky part to this build. if you want to angle the hammers up you need a way of keeping the angle consistent. Of course, if you don’t mind, you could also stick the hammers perpendicular to the board, and make all the cuts straight, but I wanted to angle my hammer heads:

I eyeballed the angle I thought looked good and set the blade of my miter saw to match it.

The head of the hammer will make it impossible to line the hammer against the fence of the saw so I used a wooden block to prop it out. Be careful to hold onto the hammer carefully when making the cuts so the hammer doesn’t kick back towards you!

The head of the hammer will make it impossible to line the hammer against the fence of the saw so I used a wooden block to prop it out. Be careful to hold onto the hammer carefully when making the cuts so the hammer doesn’t kick back towards you!

REMEMBER! When cutting your hammers, make sure you angle the cut correctly relative to the claw or face of the hammer head. Since I wanted the claw side up I made sure the cut angled INTO the claw side.. (away from the face.)

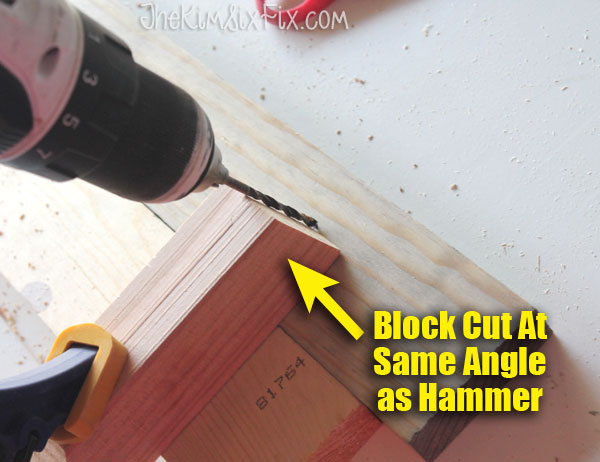

Now you have to attach your hammers to the board. This gets tricky since you want to pre drill the holes at the correct angle. To do this I created a ‘template’ block (a 2x2 board cut at the same angle as I cut the hammer handle) so I would have a line to follow when drilling.

To see this technique in action, here is a periscope broadcast I did, demonstrating the technique:

After it dried, all that was left was for me to actually attach the hammers. I pre-drilled down the center of the hammers, and then inserted a screw into the pre-drilled holes though the board. Then I rotated the hammer onto the protruding part of the screw.

…make sure to get them nice and tight, since you don’t want them to rotate.

And there you have it. I attached my rack with large screws directly into the studs (to support a lot of weight) but if you wanted to make the screws you could hide the screws under the hammer and then screw the hammers on once the board was attached to the wall.

Like I said earlier.. the beauty of this “coat rack” is that it isn’t necessarily for coats.. You can hang anything on it!

I chose my expansive extension cord collection (note the little wine cord cord ties I whipped up before.. I still LOVE those!!)

The thing that makes the claw hammers so great for use as hooks is that nothing can slide off. The claw is shaped like a hook, which means I can pile the huge 75 foot cords onto each hammer and they stay contained.

I’m so happy with my nice organized cords.

And of course.. if it ever rains, I can go back to using my hammers as a coat rack...

..nawww.. who am I kidding?

In case you didn't see yesterday's announcement.. don't miss your chance to partake in your own monthly challenge..and possibly win $1000! (Details on yesterday's post)