This style chair is also called a “Lyre Back chair" because of the greek inspired motif on the seat back. Famed American furniture maker, Duncan Phyfe made this style of chair very popular back in the 1800s. “Real” harp back chairs from that time period can be worth thousands of dollars. This is clearly a modern reproduction, probably from the 40s. It wasn’t marked, so I didn’t feel bad updating it.

Original Phyfe chairs are almost always made out of red mahogany and even the reproductions tend to go with that look. This chair clearly was clearly not mahogany. (If it were I'd have cut it up for a project like this!) The scratches revealed a much lighter wood underneath. Even though finish had deep scratches and the seat was damaged, I figured it was only three bucks. If it didn’t work out I wasn’t out much.. less than a cup of my daily Starbucks, so I brought her home.

Original Phyfe chairs are almost always made out of red mahogany and even the reproductions tend to go with that look. This chair clearly was clearly not mahogany. (If it were I'd have cut it up for a project like this!) The scratches revealed a much lighter wood underneath. Even though finish had deep scratches and the seat was damaged, I figured it was only three bucks. If it didn’t work out I wasn’t out much.. less than a cup of my daily Starbucks, so I brought her home.  In the past two days I completely transformed it. And she is so pretty now, I’ve decided to keep it and use it to replace my yuck-o office chair in my sewing studio. (She no longer looks like a Duncan Phyfe piece, that is okay, since she never really was!)

In the past two days I completely transformed it. And she is so pretty now, I’ve decided to keep it and use it to replace my yuck-o office chair in my sewing studio. (She no longer looks like a Duncan Phyfe piece, that is okay, since she never really was!) Sure, it is just another chalk paint makeover, but the fun part comes in with the new seat fabric. I replaced the NASTIEST fake pleather coated board.

Sure, it is just another chalk paint makeover, but the fun part comes in with the new seat fabric. I replaced the NASTIEST fake pleather coated board.  And in it’s place is this perfect baby blue and orange paisley home dec fabric. (Only $6.99 a yard!)

And in it’s place is this perfect baby blue and orange paisley home dec fabric. (Only $6.99 a yard!)  My total investment in the chair was less than $8, but she looks like a million bucks!

My total investment in the chair was less than $8, but she looks like a million bucks!This project wasn’t without a little elbow grease. Someone had deliberately carved the high gloss finish and the legs and seat were badly chipped. I didn’t want to just paint over it, since I knew the damage would show, so I decided to sand down the entire chair.

A few passes with 120 grit sandpaper on the random orbit sander stripped the finish right off. I sanded hard enough to remove any hints of scratches or chips.

It took a good while, I probably spent about 2 hours just sanding (especially since there were a lot of nooks and crannies) but in the end it was worth it.

It took a good while, I probably spent about 2 hours just sanding (especially since there were a lot of nooks and crannies) but in the end it was worth it.  After sanding, a good wipe down with disinfecting wipes. This is the same trick I used when painting cabinets, and I stand by Lysol or Clorox wipes as THE BEST TACK CLOTH you can buy. Disposable, grease cutting, in expensive, plus they smell good.

After sanding, a good wipe down with disinfecting wipes. This is the same trick I used when painting cabinets, and I stand by Lysol or Clorox wipes as THE BEST TACK CLOTH you can buy. Disposable, grease cutting, in expensive, plus they smell good. I had some Serenity Blue Chalked paint by Rust-Oleum left over from the baby’s rolling toy box and I decided to use that.

I had some Serenity Blue Chalked paint by Rust-Oleum left over from the baby’s rolling toy box and I decided to use that. It took two coats since the finish was so uneven and I wanted to make sure none of the dark areas showed through.

It took two coats since the finish was so uneven and I wanted to make sure none of the dark areas showed through.  Next I tackled the seat cushion. I stripped not one, not two.. but THREE layers of upholstery off this sucker. And each was nastier than the first.

Next I tackled the seat cushion. I stripped not one, not two.. but THREE layers of upholstery off this sucker. And each was nastier than the first.  I used a channel locks to remove all the staples and threw out all the fabric as well as the the cotton padding, which was shot (plus I knew if i used this in my sewing room I'd be sitting for a lot of hours so I wanted something thicker.)

I used a channel locks to remove all the staples and threw out all the fabric as well as the the cotton padding, which was shot (plus I knew if i used this in my sewing room I'd be sitting for a lot of hours so I wanted something thicker.) I trip to the Fabric Store for my fab $7 fabric (1/2 a yard was plenty) plus 1 inch high density foam.

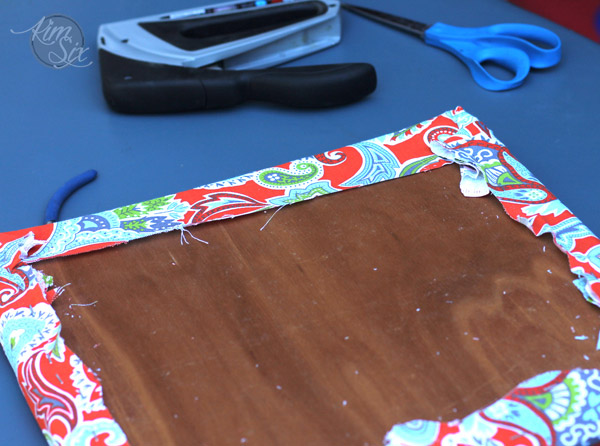

I trip to the Fabric Store for my fab $7 fabric (1/2 a yard was plenty) plus 1 inch high density foam.

I stapled it down using my Arrow stapler, which was great since i needed the extra power to go though the thick layers of fabric into the wooden board.

I re-used the original screws and attached the seat.. and my project was done.

I re-used the original screws and attached the seat.. and my project was done.  Bought the chair on Monday morning and by Tuesday night it was making it’s home in my office (but not before my 3 year old helped test it out.)

Bought the chair on Monday morning and by Tuesday night it was making it’s home in my office (but not before my 3 year old helped test it out.) I’m pleased as punch with my $8 “investment".

I’m pleased as punch with my $8 “investment".