Okay guys, I couldn’t resist the sirens song.. The call of concrete was just too strong and so, once again, I’m bringing you another fun DIY/Craft project out of my favorite composite material. I just love working with the stuff, and using it for everyday items (instead of building.. I don’t know.. a sidewalk or something) just seems so much more fun!

Okay guys, I couldn’t resist the sirens song.. The call of concrete was just too strong and so, once again, I’m bringing you another fun DIY/Craft project out of my favorite composite material. I just love working with the stuff, and using it for everyday items (instead of building.. I don’t know.. a sidewalk or something) just seems so much more fun!Today’s project is this totally mod desk clock (I suppose you could hang it on the wall, but since we live in Earthquake territory, the idea of a cement block coming down on my head seems EXTREMELY unappealing). I thought I would guild the lily by jumping on the “dipped” trend and color blocking one side with a fun and funky color and this was also my first time playing with dyed concrete, so that was another awesome adventure.

For now I’ve put the little guy on a low shelf in the living room, next to my other DIY projects, since I apparently love to surround myself with my own projects. (Sorry Home Goods stock holders, but I’ve been spending a lot less money there these days!) And I have reduced the risk of head injury during a natural disaster.

For now I’ve put the little guy on a low shelf in the living room, next to my other DIY projects, since I apparently love to surround myself with my own projects. (Sorry Home Goods stock holders, but I’ve been spending a lot less money there these days!) And I have reduced the risk of head injury during a natural disaster.

Here is how inspiration originally struck. I found this pendulum clock movement in the clearance bin at JoAnn’s. It was only TWO BUCKS! I had no early clue what I was going to do with it, but since I’ve been on a DIY clock makin’ kick lately, I thought “I better buy this!”

You can find this exact kit on Amazon, for like 11 bucks, but since I didn’t use the swinger thing (I guess I should call it the real name.. the pendulum) if I was buying a movement with the intention of this project I’d probably get one that is more modern (and cheaper!) Plus that would look AWESOME against the black concrete.

vs

Concrete Clock Supply List:

- Clock movement- Laminated MDF board that is AT LEAST 2x wider than your longest clock hand. (Since it will go around in a circle this means the clock face will be wide enough.. i know the trigonometry is a pain, but go with me here.) My second hand was about 3 inches long so I used a 8 inch wide shelf board.

You want to use a board that was coated in a super smooth surface (the reason I used a Rubbermaid shelf board instead of regular wood) so the face of the clock would be smooth, the moisture won’t absorb and cause the wood to swell, and it will release easily. Plus it was only 5 bucks. A “real” board was double that for an 8 inch width

- 8 inch long scrap boards (as wide as you want the clock thick) I used 4 inch wide boards

- Block of scrap wood larger than the clock movement (this is going to create a void in the back of the clock to hold the movement mechanism)

- Wooden dowel (to create a hole for the clock movement to stick through)

- Drill bit the size of the dowel

- Concrete (I used Mortar Mix since I had it lying around, but there is “craft cement” that is much lighter and friendlier)

- Cement Color (optional.. but awesome. I used the color Charcoal)

Tools:

- Saw to cut board

- Drill or drill press

- Bar Clamps

So first I cut my shelf down so it was a perfect 8 inch square (you could make it a rectangle I suppose, but a square made sense to me) and then I drilled a hole in the center which was the exact diameter of my dowel.

So first I cut my shelf down so it was a perfect 8 inch square (you could make it a rectangle I suppose, but a square made sense to me) and then I drilled a hole in the center which was the exact diameter of my dowel.

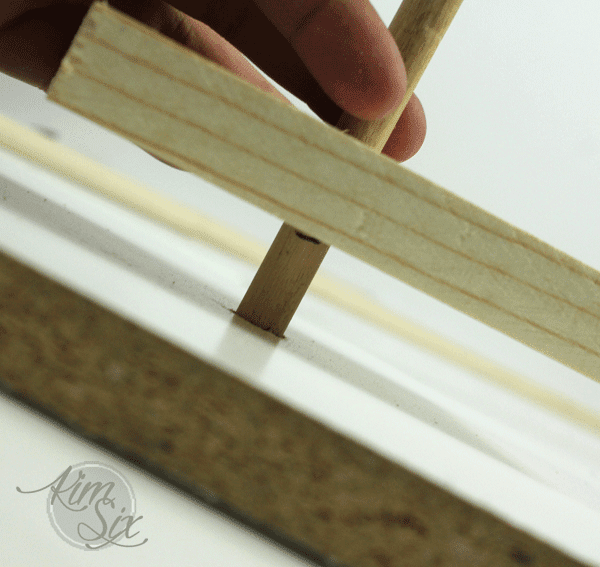

Next I measured exactly how long the movement arm extended out (after spending a bunch of time figuring this out, I realized it said right on the package “for 3/4 inch face plates” which means the face couldn’t be more than 3/4 inches thick.) So I marked that on my dowel. I also cut my scrap block and drilled a hole in that.

Here is what the assembly process looked like. You can see my dowel,with my 3/4 inch mark stuck into the 8x8. I slid on my scrap board and made a second mark for where I wanted the TOP of my scrap board to stop (since i wouldn’t be able to see the bottom mark once it was sunk in the concrete).

Next I clamped my sides on the outside to form a box. I used clamps so I could take them off easily. You could screw them together too, but I was too lazy to find screws. I originally tried to add two small pieces of trim to give the face a notch on the top and bottom, but I had to remove them since I knew the middle would only be 3/4 inch thick and these extra notches would make the concrete too fragile.

Next I clamped my sides on the outside to form a box. I used clamps so I could take them off easily. You could screw them together too, but I was too lazy to find screws. I originally tried to add two small pieces of trim to give the face a notch on the top and bottom, but I had to remove them since I knew the middle would only be 3/4 inch thick and these extra notches would make the concrete too fragile.

As for the concrete itself, since I was using mortar mix (which is pretty coarse stuff) I used a sieve to remove all the small pebbles.

I was left with the fine cement dust to which I added my concrete color (I just eyeballed it. I had no idea how much I actually needed.)

Add a little water until it was thick milkshake consistency and pour it into the mold.

Once it was in the mold I smoothed my scrap back down into the concrete until I got to the line and then I tapped the whole setup up and down to get the mix to settle and to knock out any bubbles.

While the concrete was still a tad soft, but set up (about 10 minutes) I removed the block, and the sides (if you wait for the concrete to harden it will be really hard to remove the block.)

After a few hours I was able to remove the clock from the shelf board. This is what the front looked like. Super smooth. LIKE BUTTAH!

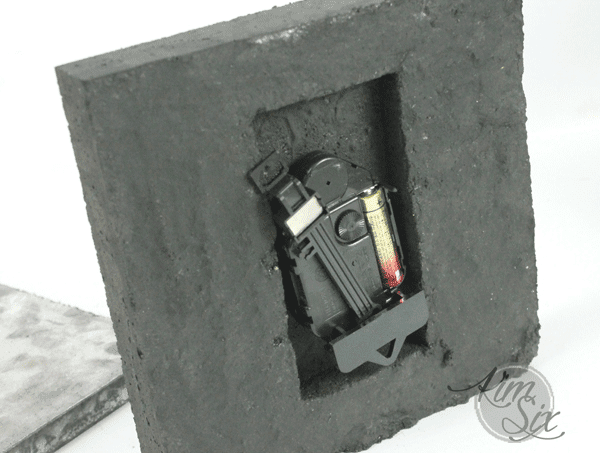

After a few hours I was able to remove the clock from the shelf board. This is what the front looked like. Super smooth. LIKE BUTTAH!  The back, on the other hand, was ROUGH. But that is okay, nobody looks at the back. The clock movement fit perfectly (not sure why I installed it upside down.. but whatever!)

The back, on the other hand, was ROUGH. But that is okay, nobody looks at the back. The clock movement fit perfectly (not sure why I installed it upside down.. but whatever!) I added the hands and a battery and this sucker was ready to go:

I added the hands and a battery and this sucker was ready to go:

Don’t you love the black? So much more ‘concrete-y”!

And the face was so smooth except for the micro bubbles. I LOVE IT.

And the face was so smooth except for the micro bubbles. I LOVE IT.  But the problem was, it was so plain that when it sat on my shelf nobody would notice it. THIS CLOCK IS AWESOME.. it needs to scream for attention.

But the problem was, it was so plain that when it sat on my shelf nobody would notice it. THIS CLOCK IS AWESOME.. it needs to scream for attention.  Enter the crazy teal paint. I had this super bright front door paint from Modern Masters (this post isn’t sponsored or anything.. I just had it and my HOA would NEVER approve that door color so I thought I’d use it for this!) Ironically the color is called “Tranquil" (who was smoking something when they named that?!)

Enter the crazy teal paint. I had this super bright front door paint from Modern Masters (this post isn’t sponsored or anything.. I just had it and my HOA would NEVER approve that door color so I thought I’d use it for this!) Ironically the color is called “Tranquil" (who was smoking something when they named that?!)

I used my trusty Frog Tape (which has never failed me for perfect paint lines) and went to town:

Is that not the most funky and fun clock you have ever seen?

Like seriously. I am in love. And that is saying a lot, since I already was in a pretty serious relationship with a few other concrete projects in my life.